During exploration and remediation work in contaminated areas, air monitoring for gases and vapours often plays an important role in occupational safety. In addition to monitoring acute hazards such as fire, explosion, oxygen deficiency with multi-gas measuring devices, chronic hazards to workers must also be assessed using suitable measuring devices.

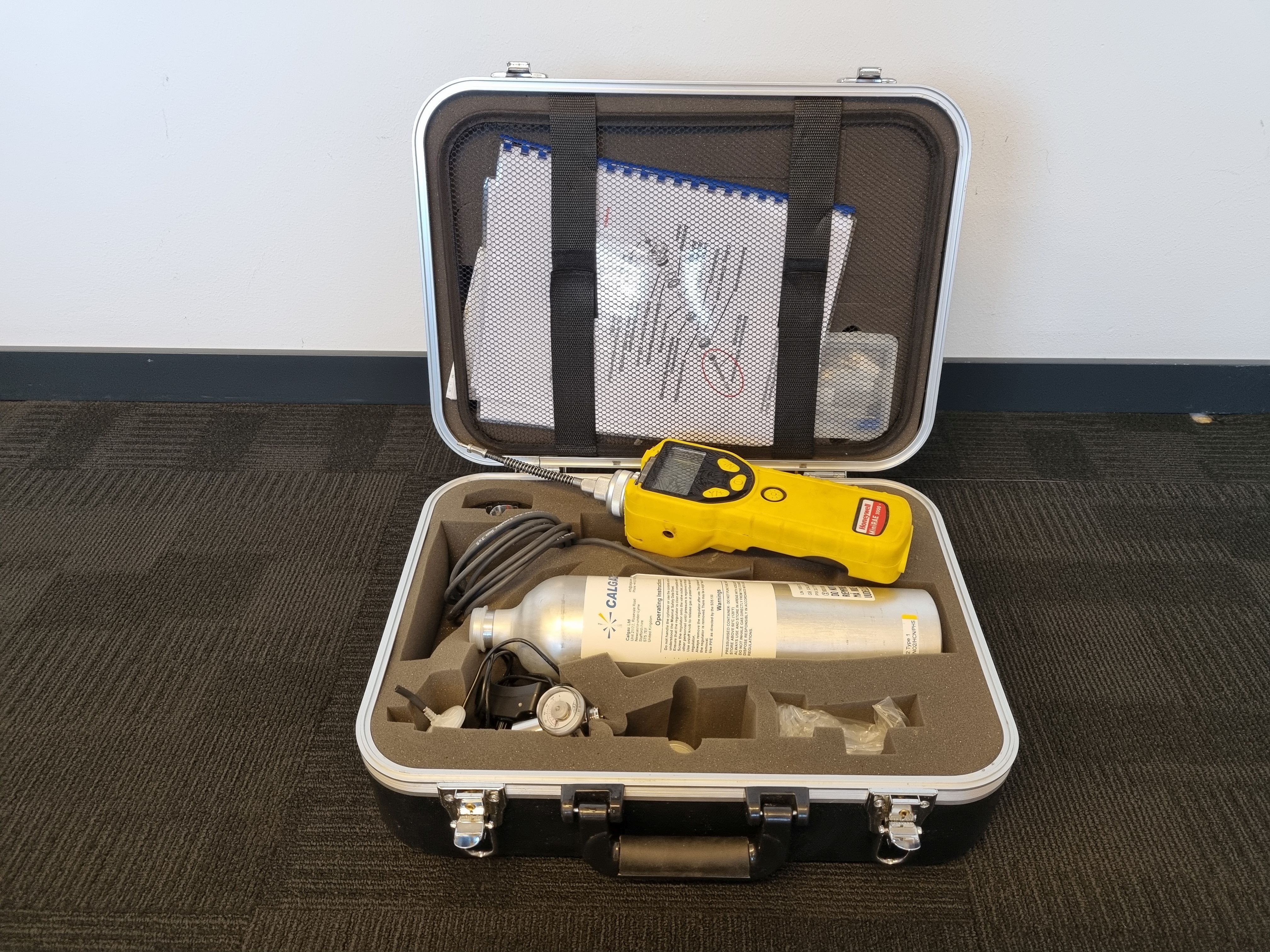

One way to monitor the quality of the breathing air is to use a photoionisation detector (PID). In addition to an internal pump for drawing in the ambient air to be examined, this measuring device has a UV light source and a so-called ionisation chamber as a measuring cell. Here, the aspirated pollutant gases from the ambient air are ionised by the UV light and thus become electrically conductive. This enables an electric current to flow through the measuring cell, the strength of which depends on the number of ionised particles. This current flow is electrically amplified and can be shown as a pollutant gas concentration in the display of the device by means of suitable calibrations. Calibration is usually carried out with a non-hazardous substance (usually isobutylene). A substance-related adjustment can be carried out using conversion factors, some of which are also stored in internal data beacons. However, this is only useful if the individual substances are known.

The components of the unpolluted outside air (nitrogen, oxygen, carbon dioxide, noble gases) are not ionised by the UV source, but organic solvents such as hydrocarbons can be ionised very well. The strength of the UV source is decisive for the number of detectable substances. Not all organic gases and vapours are detectable with the commercially available UV sources (9.8 eV = electron volts, 10.6 eV or 11.7 eV), whereby the required ionisation energy (in eV) is a physical substance constant. Identification of substances is not possible with a PID.

With a 10.6 eV lamp, however, a large number of organic chemicals can already be detected or measured, including alcohols, aromatics, iodides and bromides, amines, mercaptans, aldehydes, ethers, acrylates and esters, etc.

The PID can be used, among other things, for continuous air monitoring during remediation work, but it only shows sum signals for the detected substances. To assess the resulting hazard situation, the percentage composition of the individual components must be determined in advance in the laboratory in order to calculate threshold values, which, if exceeded, require further protective measures such as dilution of the pollutants by blowers. PID measurements should only be carried out by trained personnel, as the measurement results must be evaluated competently.

Other possible applications are, for example, the inspection of drill cores during remediation investigations of contaminated sites with regard to solvent contamination, the search for leaks in industrial plants or the delimitation of damage areas in the case of chemical accidents.

Prof. Burmeier Ingenieurgesellschaft mbH is available with trained personnel and the measuring equipment for the corresponding metrological support to ensure safe working on contaminated sites.